[ad_1]

Toyota Motor Company (Toyota) introduced as we speak that it’s going to enter the ENEOS Tremendous Taikyu Sequence 2023 Supported by Bridgestone Spherical 4 Tremendous Taikyu Race (5h x 1 race), to be held from July 29 to 30 on the Autopolis worldwide racing course in Oita Prefecture, with the #32 ORC ROOKIE GR Corolla H2 Idea, which runs on liquid hydrogen, and the #28 ORC ROOKIE GR86 CNF Idea working on carbon-neutral gasoline

Toyota Motor Company (Toyota) introduced as we speak that it’s going to enter the ENEOS Tremendous Taikyu Sequence 2023 Supported by Bridgestone Spherical 4 Tremendous Taikyu Race (5h x 1 race), to be held from July 29 to 30 on the Autopolis worldwide racing course in Oita Prefecture, with the #32 ORC ROOKIE GR Corolla H2 Idea, which runs on liquid hydrogen, and the #28 ORC ROOKIE GR86 CNF Idea working on carbon-neutral gasoline.

1. Evolution from the Fuji 24 Hours Race

The hydrogen-powered Corolla, cell liquid hydrogen stations, and carbon impartial gasoline have advanced within the two months because the Spherical 2 NAPAC Fuji SUPER TEC 24 Hours Race from Could 26 to twenty-eight.

1) Hydrogen-powered Corolla

-

Improved sturdiness of liquid hydrogen pump

The sturdiness of the pump, which was a problem within the Fuji 24 Hours Race, has been improved, leading to 30% enhanced sturdiness beneath comparable situations. Lubricating oil is often utilized in pumps to cut back stress via much less friction within the pump; nevertheless, lubricating oil can’t be utilized in liquid hydrogen pumps because it contaminates the hydrogen. For this race, a buffer construction might be used to cut back stress on the pump gear drive unit, aiming to permit it to complete the race with no need to get replaced.

-

Automobile weight diminished by 40 kg

Varied liquid hydrogen methods, together with security valves and piping, have been optimized primarily based on analyses of information collected in earlier checks and races. As well as, pump stress has been diminished by optimizing gasoline strain, resulting in a weight discount for the pump drive motor battery. In consequence, the car now weighs 1,910 kg, 40 kg lighter than the 1,950 kg it weighed throughout the Fuji 24 Hours Race in Could.

2) Cell liquid hydrogen stations

-

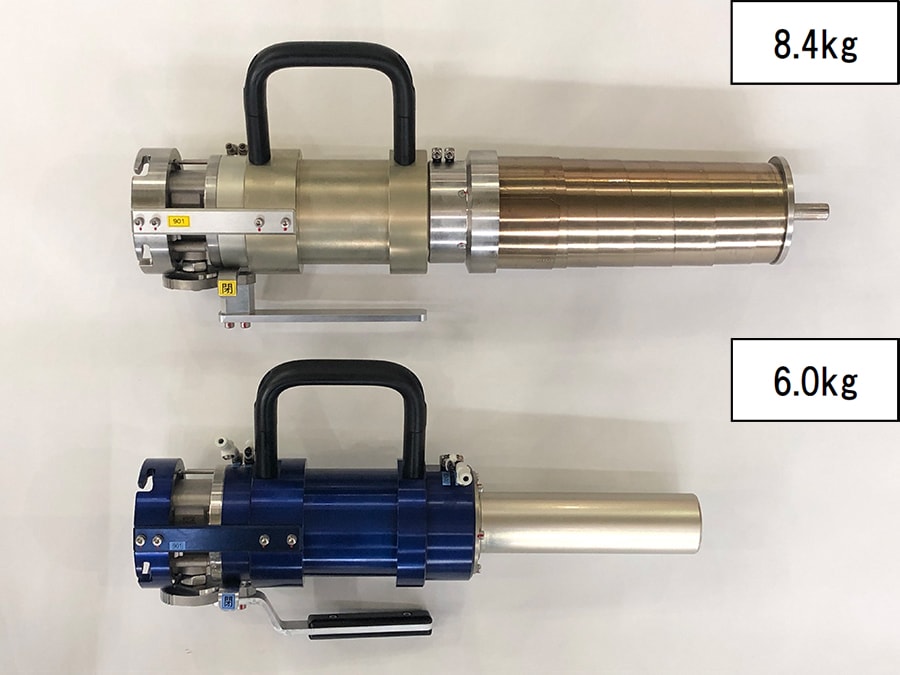

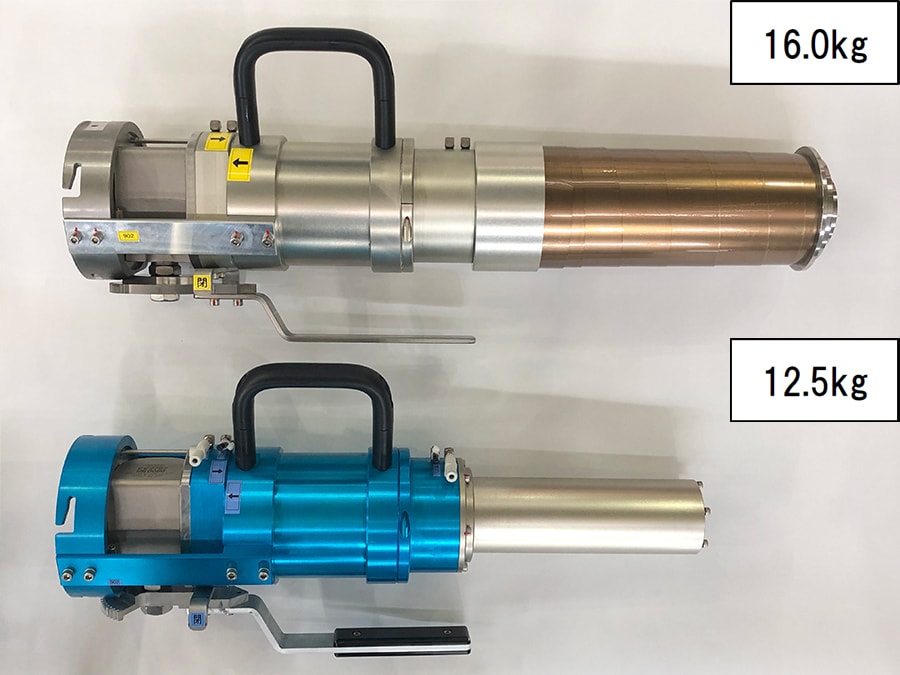

Joint and versatile hose weight diminished

We’ve got succeeded in decreasing the burden of joints and versatile hoses for the cell liquid hydrogen station that was developed collectively by Iwatani Company and Toyota. Because the joint and versatile hose weight places a burden on the employees who fill automobiles with hydrogen, decreasing their measurement and weight is necessary in getting ready for future commercialization. We diminished the burden of the filling joint from 8.4 kg to six.0 kg and the return joint from 16.0 kg to 12.5 kg by eliminating the connection cowl and altering the elements that don’t come into contact with hydrogen from iron to aluminum. The versatile hose on the return joint facet has additionally been modified to a thinner hose, decreasing the burden from roughly 4 kg to 1 kg, to cut back the burden on employees and enhance workability throughout filling operations.

Filling joint*1 Return joint*2

Each footage present the joint used throughout the Fuji 24 Hours Race (prime) and the improved joint (backside).

Again: Return joint, entrance: filling joint Versatile hose*3

Prime is pre-improvement, backside is post-improvement.

-

Automated hydrogen filling operation

Till now, all hydrogen filling operations for the hydrogen-powered Corolla, resembling opening and shutting the filling valve and stopping filling when the hydrogen reaches full capability, have been carried out manually. For this race, now we have succeeded in automating these operations via digital management. Automating hydrogen filling will allow it to be carried out effectively and error-free in a predictable time-frame.

-

Improved hydrogen filling time

A high-flow-rate filling-side cease valve developed by Fujikin Integrated might be put in ranging from this race. The filling-side cease valve is put in onto the filling port of the liquid hydrogen tank. Valve sizes improve because the move price will increase to hurry up the filling course of, making sealing tougher. Nonetheless, Fujikin’s valve has succeeded in balancing each of those elements. In consequence, hydrogen filling time*4 has been diminished to roughly 1 minute, down from 1 minute 40 seconds on the Fuji 24 Hours Race.

3) Carbon-neutral gasoline

The CNF GR86 has been racing with the newly improved carbon-neutral gasoline because the Spherical 3 SUGO Tremendous Taikyu 3 Hours Race held from July 8 to 9.

The issue with conventional carbon-neutral gasoline is that it tends to dilute the engine oil, stopping the engine oil from performing because it ought to. Along with Subaru Company, which additionally makes use of carbon-neutral gasoline in its races, and gasoline producers, we adjusted the composition of the gasoline to make it simpler to vaporize and burn. This reduces engine oil dilution and improves reliability and exhaust efficiency by decreasing the burden on the engine.

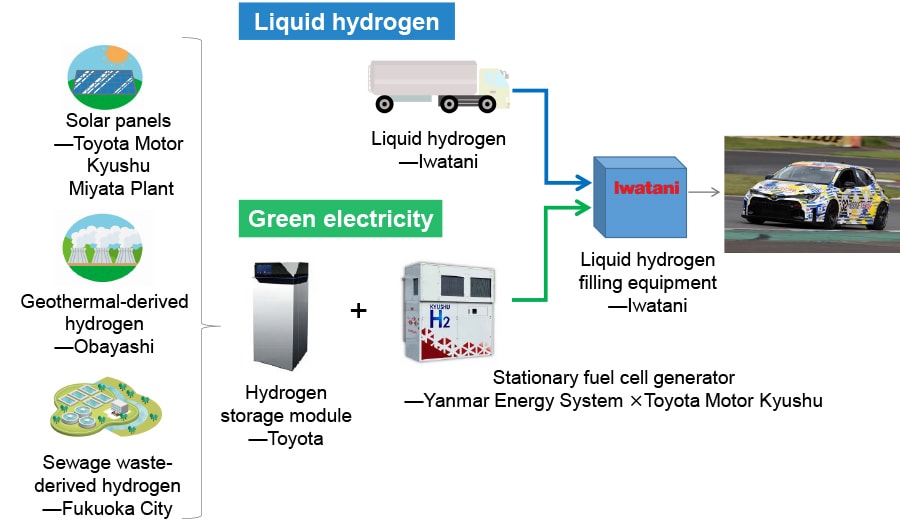

2. Progress of efforts to realize carbon neutrality with companions in Kyushu

Our native firm and municipality companions in Kyushu, who’ve come collectively to realize carbon neutrality, have been additional accelerating their efforts.

Efforts of companions in Kyushu

| Obayashi, Toyota Motor Kyushu, Fukuoka Metropolis |

A gasoline cell generator has been put in within the pit to energy the cell liquid hydrogen station for the hydrogen-powered Corolla. Three kinds of Kyushu-produced gaseous hydrogen are getting used: geothermal-derived hydrogen from Obayashi Company, solar-generated hydrogen from Toyota Motor Kyushu, and sewage biogas-derived hydrogen from Fukuoka Metropolis.  |

|---|---|

| Obayashi |

(Introduced on January 24, 2023) |

| Fukuoka Prefecture |

Fukuoka Prefecture launched FC coasters in its BRT (Bus Fast Transit) system in cooperation with Kyushu Railway and CJPT. It additionally promotes hydrogen undertaking initiatives, resembling supporting the introduction of Gentle-Responsibility Gas Cell Electrical Truck to logistics suppliers. https://international.toyota/en/newsroom/company/38377786.html |

| Fukuoka Metropolis |

Fukuoka Metropolis promotes hydrogen undertaking initiatives, together with the introduction of FC college lunch supply automobiles in collaboration with Toyota and CJPT. A prototype FC rubbish truck for technical research, which is scheduled to be launched by Fukuoka Metropolis and different municipalities, was unveiled for the primary time on the Autopolis occasion sq.. https://international.toyota/en/newsroom/company/36884314.html |

Toyota will proceed to speed up improvement by refining vehicles and other people within the difficult world of motorsports. It is going to additionally proceed to evolve along with its companions to create a good higher carbon-neutral society.

*1 Filling joint A joint for filling automobiles with liquid hydrogen

*2 Return joint A joint that returns vaporized hydrogen to the filling station

*3 Versatile hose A hose connecting the joint to the station

*4 Hydrogen filling time Time throughout which hydrogen is definitely flowing after the hydrogen filling nozzle is connected

SOURCE: Toyota

[ad_2]